Published on Jan. 26, 2023

Biosecurity at the poultry farm: a basic tool to ensure poultry health and welfare

Biosecurity is an important management tool for poultry production. It involves planning and taking steps to protect domestic poultry flocks. These measures help prevent unwanted organisms from entering the flocks. Reviewing basic biosecurity plans for poultry farms are important.

This is especially true now because of recent outbreaks of highly pathogenic avian influenza. This virus affects many areas around the world, including both wild and domestic birds. These outbreaks impact the economy, health, and welfare of birds.

Why is chicken biosecurity important?

Today, it is clear that biosecurity is important. Everyone in the egg and poultry sector must understand why they should strictly follow it.

- Economic reasons: pathogens affect the health, welfare, and technical performance of poultry.

- Public health reasons: producers must guarantee that eggs and poultry meat are safe for human consumption.

- Legal reasons: to ensure compliance with mandatory national, regional and/or local regulations

Finding possible ways infectious diseases enter is the first step. This helps people assess risks and create a good biosecurity protocols in poultry. The main pathways for the spread of pathogens are:

- Airborne transmission

- Transmission by contaminated feed or drinking water

- Transmission by contact:

- Direct contact: between infected birds and healthy birds in close contact

- Indirect contact can happen through equipment, materials, and vehicles. It can also occur via live vectors like animals. This includes wild birds, livestock, pets, rodents, and insects. People can also be vectors, such as farm workers, maintenance staff, and visitors.

Structural biosecurity

This concept encompasses all aspects related to facilities and equipment. Farmers should build poultry farms to improve biosecurity. This keeps unauthorized people out of production areas. It also prevents access by other animals, both domestic and wild.

Among the key aspects to consider are the following:

- All construction materials should be chosen to allow for effective cleaning and disinfection.

- The perimeter will have a fence with one access gate. This gate will always stay closed. We will post "No trespassing" signs, allowing access only for authorized personnel.

- Fumigation station for vehicles entering the farm, preferably an automatically activated disinfection arch, including a disinfection basin. Only essential traffic should have access to the farm.

- Park other vehicles outside the biosecurity zone. Feed storage silos should be near the perimeter fence. This allows them to fill from the outside. It also reduces risks from feed transport trucks.

- Sheds should have a 1 to 2 meter wide strip of concrete, gravel, or cut grass around them. You must always keep this area clear of waste, weeds, garbage, and unused equipment.

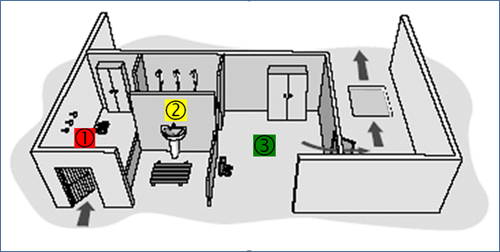

- Keeping this area near the house in good shape will lower hiding spots for pests. Reducing nesting areas for wild birds will also keep rodents away from the house (Image 1).

- Farmers should build poultry houses to block birds and rodents. They should seal entrances or cover them with chicken wire.

- Regularly check and maintain areas of the house where animals can enter. Give particular attention to high-risk areas such as air inlets, extractors, egg conveyors, litter pits, and drains.

- Maintenance of an adequate drainage system to avoid the accumulation of water that could attract migratory birds.

Operational biosecurity

This concept includes all routine farm operations. These include personnel entry, vehicle entry and disinfection, pest control, and waste disposal. The farm operating procedures manual must clearly describe these routine operations.

- Farmers must dispose of all farm waste safely. They should use methods such as incineration, composting, or removal by specialized waste management companies. All disposal methods must comply with local environmental regulations. Preferably, they should keep dead birds in freezers or sealed containers until removal or disposal.

- Drinking water and cooling system water, such as in foggers and evaporative panels, must meet good sanitary standards. An efficient water treatment system should maintain quality. Keeping water tanks closed prevents wild birds from contaminating the water with harmful microorganisms.

- Pathogens can spread through feed due to contaminated raw materials, cross-contamination after production, or during transport. Feed mills should always follow good manufacturing practices. Chemical and thermal treatments help reduce the risk of disease in feed. To prevent contamination by rodents or wild birds, keep silos closed and clean up any spilled feed immediately.

- A control program must target rodents, wild birds, and pests like flies, mites, and darkling beetles (Alphitobius). Install bait stations along house walls and in areas with high rodent activity. Check stations weekly and replace bait as needed. Keep a detailed record of each station's location, usage, chemicals used, and bait replacement frequency.

- Moving or sharing equipment between facilities can spread disease. Each farm should have its own mobile equipment, such as scales for weighing birds. If farms must share equipment or materials, they must thoroughly clean and disinfect them before use. Store only essential equipment in the storage room and keep it tidy to reduce hiding spots for rodents.

Staff and visitors

People entering the farm are the main carriers of disease. This includes farm employees, veterinarians, truck drivers, vaccination teams, and maintenance workers. Limit visits to only those necessary and strictly prohibit unauthorized persons.

- Each farm, ideally each house, should have a single access point and a well-designed changing room. A physical barrier must clearly separate the "dirty zone" from the "clean zone" (Image 2).

- The dirty area should have a clothes rack for outside clothing. Install a shower if possible. If not, provide a sink with bactericidal soap for hand washing.

- The clean area should have a closet with clean clothing, including coveralls and disposable caps. It must also provide clean footwear for farm use only. A footbath with disinfectant should be available.

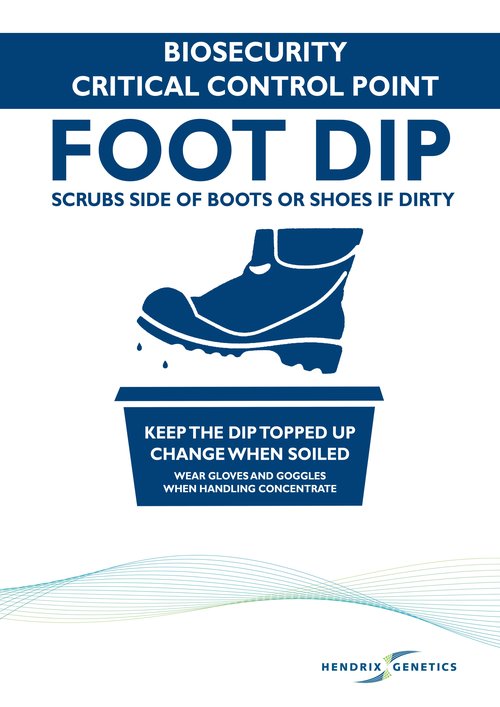

- Poorly managed footbaths can spread contamination. Clean them daily and refill with fresh disinfectant. Sunlight, rainwater, and dirt can weaken disinfectant effectiveness. Shoe soles can carry pathogens. Brush them before using the footbath and clean them after each visit (Image 3).

- Farm personnel must avoid contact with other poultry or wild birds. They must follow rules for wearing designated clothing and footwear in the clean area. Washing and disinfecting hands is essential before starting work, after breaks, after using the toilet, and whenever hands are dirty.

- Hands, hair, and clothing can become contaminated with dust containing microorganisms responsible for the spread of diseases from one farm to another. The sequence of visiting different flocks should always start with the youngest and healthiest flocks and continue with older flocks or flocks with lower biosecurity standards.

- Changing rooms must have mandatory showers for all visitors. Farm employees should shower before entering. This is a must if exposed to risks, such as visiting older or unhealthy flocks. Deny access to any visitor who poses a risk to bird health and reschedule the visit.

- Visitors and service personnel should complete and sign a visitor log before entering the farm. Keeping a detailed record of foot traffic helps trace the source of health issues. It also allows the farm owner to alert recent visitors if a disease is confirmed.

Figure 2. Diagram of a changing room with clearly delimited areas: (1) Dirty area (2) Transition area with shower and washbasin (3) Clean area

Cleaning and disinfection

Clean and disinfect thoroughly after each flock to reduce pathogens and health risks before restocking. This key biosecurity step should cover poultry houses, storage areas, equipment, and surroundings. Disinfection is only effective if all organic matter is first completely removed.

In any cleaning and disinfection program, the procedures to be followed should be established, detailing each step of the process. Very schematically, the different phases of the program are as follows:

- Removal of waste: live animals, dead animals, feed scraps, poultry manure, litter, feathers. Dismantling of equipment. This is the moment to use chemical products against insects or mites (while the house is still warm) and to place abundant bait against rodents.

- Preparation: flushing of the drinking water circuit followed by refilling with detergent and descaling solutions. Soaking of all surfaces with detergent solutions. Vacuuming and manual cleaning of areas that cannot be wetted. Visual control of the cleaning.

- Pressure washing of the buildings, preferably with detergents and hot water, not only internal surfaces, but also accesses, following a logical sequence: ceilings first, continuing with walls and finishing with the floor, and always from the inside to the outside. Washing of all equipment and dismountable material.

- Mounting of equipment in the shed when dry

- Disinfection: Spray all surfaces of the building and equipment previously washed with a disinfectant solution. Cleaning of water tanks and pipes to eliminate biofilm. New disinfestation.

- Visual inspection of cleaning and disinfection effectiveness

- Final fumigation

Finally, it is important to stress that, to implement a successful and effective biosecurity program, all measures must be simple, easy to understand, accepted by all people involved and monitored regularly. A biosecurity plan is like a chain—it’s a low-cost way to keep your birds healthy, but every link has to be strong.

Figure 3. Good maintenance of the footbath is essential to ensure its effectiveness.