Published on Nov. 30, 2020

The importance of feed particle size (granulometry) in laying hens

Feed structure (in particular feed particle size) is an often overlooked aspect of egg production. Egg producers should not assume that chicken feed is of a uniform size and homogeneously mixed, or that the feed mill is always providing the ideal mix of particles in a ration.

Feed granulometry affects the birds’ feed consumption (1), therefore we recommend checking the feed granulometry on a regular basis. The structure of the feed, including both the particle size and the uniformity depends on the following characteristics: the ingredient composition, the grain characteristics and the milling method (2;3).

When feed is presented in the form of a good quality crumb, it will be easier for the chickens to consume, it reduces the time that it takes to consume the feed and as a result it will encourages the development of the chickens (1). Therefor it is recommended to use a crumble diet from day 0 to 4/5 weeks of age of the chick and followed by a mash diet with the recommended particle size as below specified (1). Please be aware that mash diets are more sensitive for selective eating by the chickens, particle size is there for more critical when compared to pellets or crumbles (3). Besides, particles which are too fine will result in a reduction in feed consumption (1), the right balance between the different particles is therefor key. If segregation occurs, the different ingredients and nutrients are separating (4).This can negatively affect the chickens’ daily nutrient intake (4). Mash feed, with the good particle size distribution, will allow good growth and the proper development of a robust digestive system (1). There is no standard method of particle size analyses yet (5). However, dry sieving is an appropriate method for non-expanded feed (5). Therefore, Hendrix Genetics recommends using the feed sieve mentioned in this article, and to follow the different steps as described in this manual. The result of your feed sieve analyses will give you a fast and reliable reflection on the feed structure of your poultry diets.

The Effect of Feed Particle Size on the Digestive Tract

The development of the digestive tract is heavily influenced by feed particle size. In general, chickens consuming feed containing large particles will develop bigger and more muscular gizzards, these birds will also develop longer intestinal tracts. The larger the feed particle, the more time the particle will spend in the gizzard. The function of the gizzard is to grind the larger feed particles into smaller particles before they are able to enter the small intestine. These larger feed particles have also longer transit time when passing through the gastro-intestinal tracts. It is known that birds that are fed with optimum particle sized diets have longer microvilli in their intestines. These longer microvilli result in increased absorptive surface areas, this directly affects the digestibility and nutrient absorption in a positive way.

When the chicken feed is composed of too many fine particles (<0.5mm), the fine feed particles will pass quickly through the gizzard as no grinding is required. Once the particles have passed the gizzard, they will enter the proventriculus. The result of too many fine feed particles is a small gizzard, enlarged proventriculus and reduced intestinal length. We strongly advise not too feed chicken diets containing too high levels of too fine particles!

Recommended Feed particle size

Feed particle size has a large impact on the chickens' feed intake. We advise to increase the feed particle size with the age of the chicks. As the chicks grow, they will develop the size of their beaks, their gizzards and the digestive tract. It is well known that laying hens are selective eaters, i.e. laying hens have a clear preference for the larger particles. The older the bird(chick) becomes, the higher the preference for the larger feed particles. It is recommended to allow the birds time to finish the feed during the middle of the day, this will help to clean the feeders and to prevent the accumulation of small feed particles (referred as empty feeder technique). The larger feed particles are often the coarse grinded grains or corn (energy), while the fine feed particles usually contain the vitamins, amino acids, phosphorus and the essential trace minerals. As the fine particles play a crucial role in persistency of egg production and egg shell quality selective eating should be prevented at all times. As an egg producer you should carefully monitor the eating behavior of your flock. The empty feeder technique should already be applied after the first 4-5 weeks of rearing, as this will train the birds to eat well and develop a good crop.

Using the feed Sieve

Method of Sampling

The most important step for accurate analysis is taking a representative sample (6) from the feeders. Take 5-6 subsamples from different locations, mix them together and reduce the sample size, preferably via a quartering procedure (6). For the quartering procedure, mix the samples, spread them out, split the sample up again in four equal parts and sieve the two opposite quarters (6)

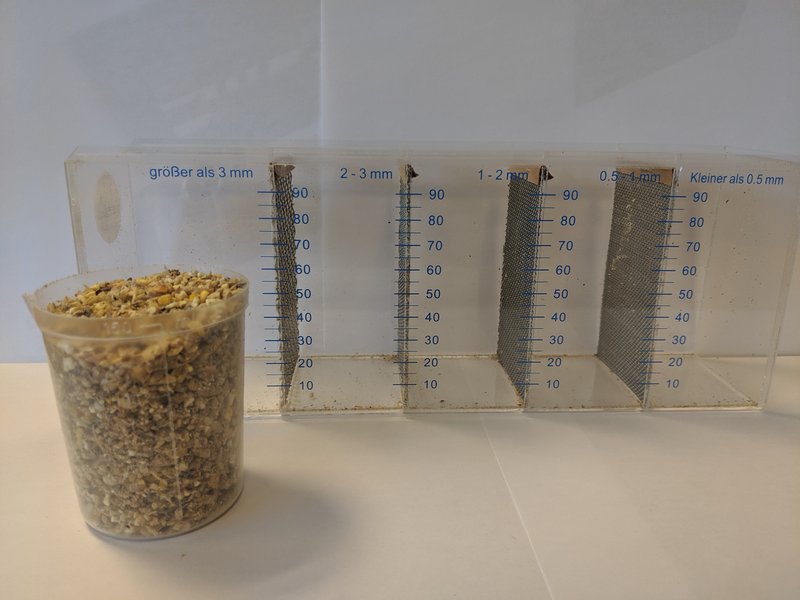

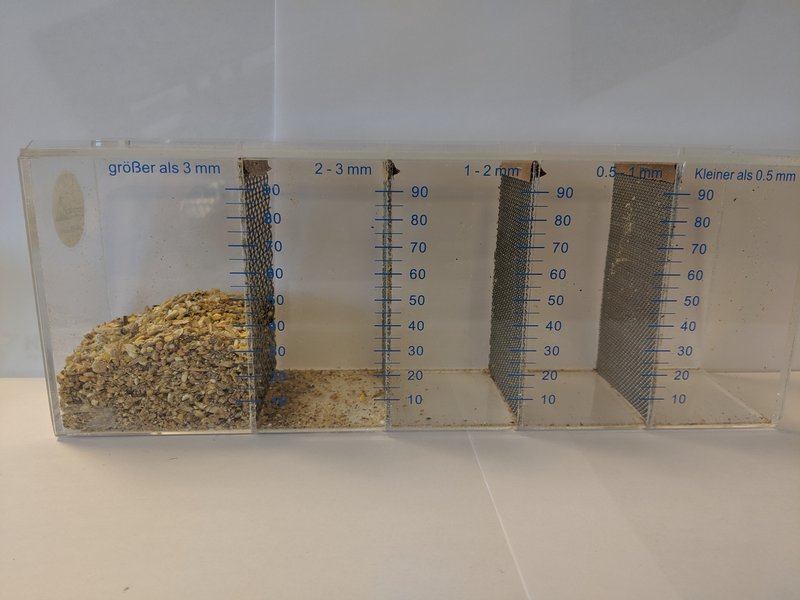

Figure 1 example of the feed sieve

Method of Sieving

- Remove the lid and fill the first compartment with one cup of feed.

- Bring the lid back on the shaker and make sure it is properly closed.

example of the feed sieve with filled first compartment and closed lid

- Turn the sieve, so it stands vertically with the filled compartment at the top.

- Shake the sieve firmly. Stop shaking when all the fine particles fell to the last compartment for at least 10 seconds.

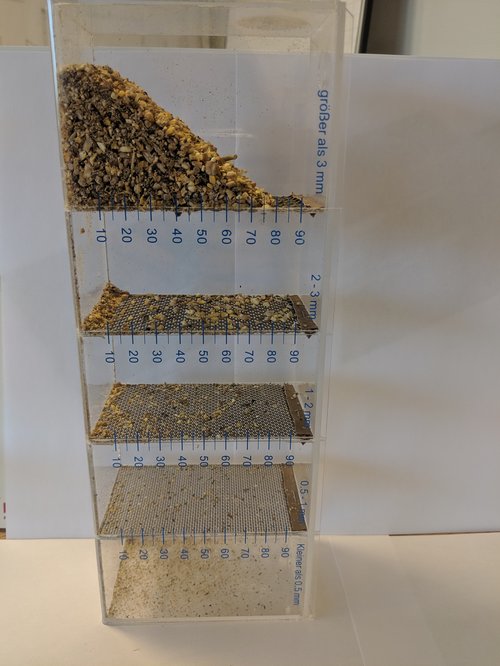

- Return the sieve sideways and record the values per compartment.

- Calculate the percentage by filling in the values in the grey area by using a calculator or Excel

| Particle Size | Value | % | Recommended feed particle size Parent Stock & commercial laying hens |

| >3 | =value/1.4 | = total value > 3 | max 10% |

| 2 - 3 | = total value 2 - 3 | ||

| 1 - 2 | = total value 1 - 2 | max 80% (0.5 - 3) | |

| 0.5 - 1 | = total value 0.5 - 1 | ||

| < 0.5 | = total value < 0.5 | max 10% | |

| Total |

- Check if the particle size distribution is according to the recommendations.

Further Actions

If the particle size distribution is not according to the recommendation, it is necessary to check all the factors which can affect feed particle size: feed manufacturing, transportation from factory to farm and within the farm, storage, feed pans, feeder management and grinding. If the standard of minimum 80% particles between 0.5 and 3.2 mm in mash cannot be achieved for the starter rearing feed (from 0 to approximately 5 weeks of age), it is preferable to use a diet of good quality crumbs (1).

References

- Nutrition Management Guide. Boxmeer : Hendrix Genetics.

- Influence of particle size of the main cereal of the diet on egg production, gastrointestinal tract traits, and body measurements of brown laying hens. Herrera, J., et al. 2017, Poultry Science, pp. 96: 440- 448.

- Implication of milling methods, thermal treatment, and particle size of feed in layers on mineral digestibility and retention of minerals in egg contents. Hafeez, A., et al. 2015, Poultry Science, pp. 94: 240-248.

- Effect of Feed Segregation on the Commercial Hen and Egg Quality. Tang, P., Patterson, P.H. and Puri, V.M. 2006, The Journal of Applied Poultry Research, pp. 15: 564-573.

- The effects of particle size, milling method, and thermal treatment of feed on performance, apparent ileal digestibility, and pH of the digesta in laying hens. Ruhnke, I., et al. 2015, Poultry Science, pp. 94: 692-699.

- Servi-Tech Laboratories. Feed Sampling Procedures. Servi-Tech Laboratories. [Online] 2019. https://servitechlabs.com/Services/Feed/FeedSamplingProcedures/tabid/126/Default.aspx .