Published on Dec. 8, 2020

The care for eggs

Eggs are the main source of income when keeping laying hens. In general, the more 1st quality eggs you can collect from your flock, the more profitable your flock will be. Management advices are often given to improve the productive performance of your flock. This will increase the number of eggs being produced but does not often take the handling of the eggs into account. In this article we will highlight several aspects of egg collection to improve the output of 1st quality eggs.

Collection of Eggs

Nests must be always kept clean. Manure and broken eggs should be removed frequently. In littered type nests, the nesting material must be clean and free of mold and be renewed regularly. In automatic nests, plastic bottoms or pads must be cleaned periodically. Nests should be equipped with a closing or ejection system to prevent birds from staying in at night and soiling the nest. It is advised to collect eggs at least 1 time per day. We also advise to increase this in extreme hot or cold weather. Egg collecting devices such as baskets, plastic trays and belts must have holes to allow organic contamination debris to fall away from the eggshell surface and to avoid contamination of other eggs. These devices should be cleaned and disinfected before use, pay special attention to dust. Cardboard trays must better not be re-used (biosecurity). Prior to handling eggs, hands should be washed and then disinfected with a sanitizing solution. Hands should be re-sanitized frequently during egg collecting time and whenever returning from other tasks.

Floor eggs

Floor eggs should be collected quickly after lay, selecting clean eggs only as 1st quality eggs. Dirty eggs must be eliminated under all circumstances, and they should not be stored near to clean table eggs. The number of floor eggs can be reduced by following good management procedures. Prevention of floor eggs is a key factor for flock success. Avoiding this behavior requires a lot of attention at the beginning of the lay. In this section, we define floor eggs as all eggs laid out of the nest such as floor, slats, and system eggs. The three main points are:

- The nest must be more attractive and comfortable than other parts of the hen house.

- Access to the nest must be easy for birds.

- There must be enough nest boxes in the house

Light management is one of the main factors in the prevention of floor eggs:

- Light must be well spread in the laying house and shadow areas need to be avoided. Birds naturally lay in darkened areas. This can be prevented by a simple action such as replacing broken bulbs and adding light to the shadow areas.

- When possible, a progressive “lights off” process should be done. Lights underneath the system should be turned off first, followed by the lateral light this will encourage birds to go close to the nest and to sleep on slats, then finally, the central light and the lights in the system should be switched off.

- According to breed and lighting program, a variable percentage of birds will lay before “lights on” and the propensity to lay on the floor is higher for these birds. Night lights in the nest encourage these early birds to go into the nests for laying, before the general lights come on.

- Where legislation allows it, a short light period during the night (for example 1h30 of light, 3 hours after “lights off”), will delay the lay of one part of the flock and reduce the competition in the nest. This will be more efficient if the number of birds per nest is high, allowing all hens easy access to the nests.

- In some situations, adding one extra hour of light in the morning could solve a floor egg problem.

General management advice

- Any corners caused by equipment or building design are potential areas for eggs to be laid. Therefore, limiting access to corners prevents floor eggs.

- It has been observed that keeping the birds on the slats or in the aviary system for too long may increase the incidence of floor eggs. The floor scratching area should be accessible when the flock has discovered the upper area (nest, feeder, drinker).

- At the beginning of lay, frequent floor egg collection should be done several times per day. A floor egg will encourage other birds to lay in the same place.

- Ensure all the birds sleep on the slatted area or in the aviary system.

- Observing where floor eggs are laid can help to explain the reason for the behavior. This information can be very useful to help understand the problem and to develop a solution.

- Grit distribution on the floor discourages floor eggs by eliminating the building of potential nests in the litter.

- Installation of a deflection barrier between the nest boxes enables the birds to be evenly distributed, thereby diluting the pressure in particular nest boxes. This also helps to prevent the overcrowding of nests located near to partitions.

- Frequently remove the manure and litter in the litter area in order to prevent the floor of being too comfortable to serve as a nesting area. Especially for white birds it is important to remove the litter soon enough, as they have the tendency to go and lay on the litter.

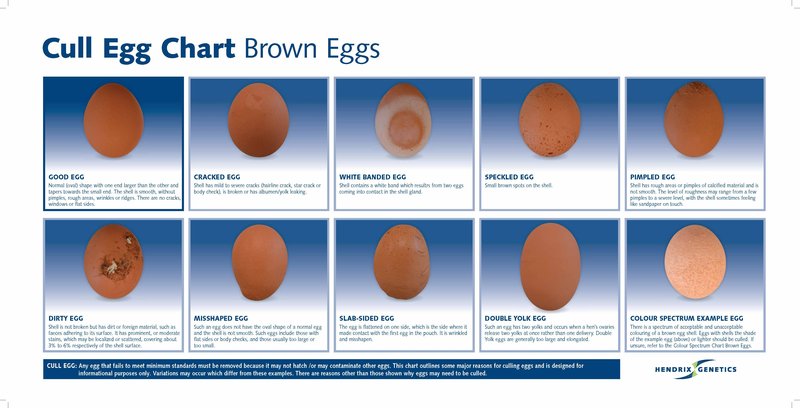

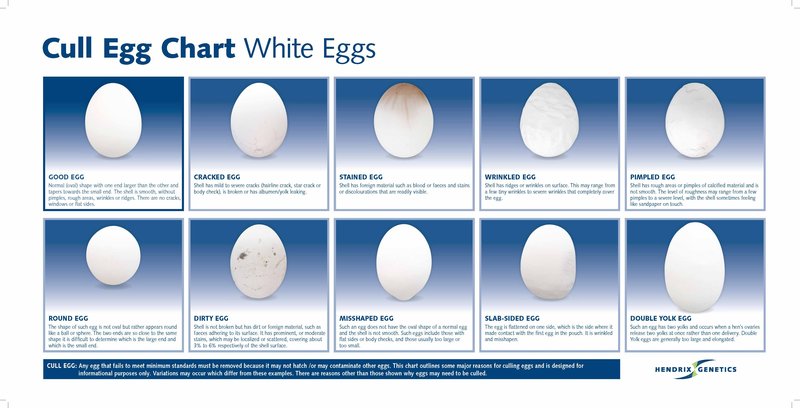

Shell Quality

Shell quality is another important external aspect when it comes to producing eggs. The shell must be smooth and free of cracks. Thin-shelled eggs tend to crack more easily, with the consequent risk of contaminating other eggs and they should not be used. At peak production, during periods of extreme temperatures, and at the end of the production period, special attention should be given to a proper balance in calcium allowances (supplementary coarse limestone or oyster shell) to ensure good shell quality.

Washing of Eggs

Washing eggs is possible, but it is not allowed in all parts of the world. It requires a well-constructed egg-washing machine, which should be operated in the correct way to avoid adverse effects on contamination and therefor shelf-life. Strictly follow the manufacturer’s recommendations regarding water quality and temperature, choice and level of sanitizer, duration of washing, frequency of change of the washing solution, rinsing and drying conditions etc. If the requirements are not met, it can result in the contamination of eggs.

Storage of Eggs

An appropriate egg storage room is required for the storage of eggs. It should be well insulated and equipped with a cooling and heating system with a humidifier to maintain a constant temperature and humidity. Room temperature between 5°C - 10°C is advised together with a humidity between 80 – 85%. Walls and roofs should be kept free of dust and floors tiled for easy cleaning and frequent fumigation. Drafts should be avoided, and mice always kept out of the egg storage room. Storing conditions should be set in order to avoid water condensation on the shell’s surface (“egg sweating”), which creates favorable conditions for microbial growth. This phenomenon occurs when stored eggs are transferred to a warmer environment and the dew point is reached. To avoid temperature fluctuations and egg sweating during transport, truck and farm egg storage room temperatures should be equal. Eggs should always be handled with care in order to avoid mechanical shocks at loading, during transport and unloading. If an egg storage room is not available on the farm, eggs must be collected from the farms to the packing station or directly to the retailer more frequent.

To Conclude

Egg quality is one of the most important factors affecting the profitbaility of your operations, whether you are a Parent Stock farmer, manager of a hatchery or egg producer, the care of (hatching) eggs should not be overlooked!