Published on Aug. 4, 2023

Egg Candling

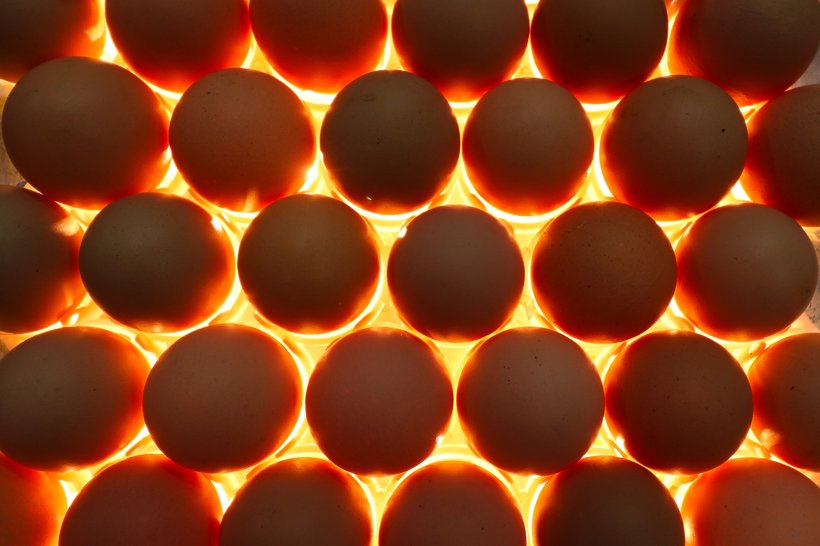

Egg candling is a process commonly used in commercial hatcheries to assess the fertility and development of eggs, particularly during the incubation period. It involves shining a light source, typically a bright and focused beam of light, through an eggshell to observe the internal contents of the egg. This illumination allows hatchery workers to visually inspect the egg's contents, which can reveal important information about the egg's viability, such as the presence of a developing embryo, signs of early mortality, or infertility. Infertile eggs and those with deceased embryos, are collectively referred to as 'clears'. Initially, this inspection can occur as early as day 5 or 6 of incubation, where an individual light is used to illuminate the eggs. However, this method is time-consuming and carries the risk of errors, such as accidentally removing a viable egg.

The potential for candling errors can be minimized by conducting the examination on day 9 or 10 of incubation. At this point, an alternative approach known as a 'candling table' can be employed. This involves illuminating the entire tray of eggs from beneath. While using a candling table is quicker than individual egg inspection, it may sacrifice a degree of accuracy. This is particularly evident when there is a high number of 'clears', as light passing through empty spaces in the tray can make it challenging to definitively identify remaining clear eggs. Many hatcheries opt to candle eggs on the day they are transferred from the incubators to the hatchers, as this proves to be the most efficient in terms of time and labor. When eggs are examined in this manner, automatic candling equipment can be utilized, which illuminates all eggs before any clears are eliminated. This approach avoids the drawback of reduced accuracy caused by light flooding.

The primary purposes of egg candling in commercial hatcheries include:

- Fertility Assessment: Candling helps identify infertile eggs that do not contain developing embryos. These infertile eggs will not hatch and can be removed from the incubation process, preventing unnecessary incubation resources from being used.

- Early Mortality Detection: Eggs with embryos that have died at an early stage can be identified and removed. This prevents the potential for contamination from decomposing embryos and allows the hatchery to allocate resources more effectively to viable eggs.

- Early identification of issues on breeder farms, during egg handling, and throughout incubation, especially when combined with egg break-out analysis.

- Hatchery Efficiency: By identifying non-viable eggs early on, hatcheries can optimize the use of incubator space, reduce the risk of contamination, and improve overall hatchery efficiency.

- Chick Quality: Candling can help improve the quality of hatched chicks. Removing non-viable eggs and identifying potential issues can contribute to higher hatch rates and healthier chicks. It also helps to estimate the expected percentage of viable chicks. Clear eggs introduced to the hatcher baskets create an unstable environment as they do not generate metabolic heat. When automatic chick separators are used, there is a risk of clear eggs breaking and leading to 'painted' chicks.

- Data Collection and Analysis: Hatcheries can gather data on hatch rates, fertility rates, and other important metrics by tracking candling and break-out results over time. This information is valuable for evaluating hatchery performance and making necessary adjustments.

- Waste Reduction: Removing non-viable eggs reduces waste and the need for disposal. In some cases, clear or infertile eggs may have alternative uses, such as for pet food or other products.

Egg candling is typically performed at various points during the incubation process, such as around day 5-6, day 9-10, and sometimes closer to the day of transfer to the hatcher. The timing of candling can affect its accuracy and the information it provides. As mentioned earlier, more advanced techniques such as using candling tables (illuminating entire trays of eggs) or automatic candling equipment have been developed to improve efficiency and accuracy.

Below we have listed some extra guidelines for the hatching egg candling process:

- Avoid candling of hatching eggs between days 11 and 14 of incubation, as this disrupts embryo movement along the egg's length axis.

- When candling hatching eggs on day 9 or 10, fill empty spaces on the setter tray by shifting remaining eggs backward to create complete rows, leaving the front rows empty.

- Remove clear eggs if they exceed 10-15% of the total. If the clear percentage is under 10%, there's no immediate need for removal before transfer.

- If more than 30 eggs are removed during candling on the day of transfer from a tray containing 150 eggs, add eggs from another tray to ensure hatcher baskets are adequately filled. Ideally, eggs should touch each other within the basket, as vibrations caused by the first chicks pipping can stimulate other chicks to start hatching.

In summary, egg candling is a critical practice in commercial hatcheries to ensure the highest possible hatch rates, optimize hatchery operations, and produce healthy chicks for the poultry industry.