Published on Sept. 20, 2019

Incubation essentials

There are a number of important factors to consider when setting up your hatchery with the right processes and systems. The hatchery floorplan must be set up correctly for biosecurity and hygiene standards as well as proper egg storage. During the incubation stage, the chick embryo requires the proper temperature, humidity levels, fresh air through ventilation, and positioning in order to develop and hatch successfully. Because the incubators are so important to the resulting chick quality and hatchability, be sure to keep up to date in proper maintenance of the machinery.

There are a number of factors to keep in mind when applying incubation settings.

- Breeding stock type (for example, white and brown layers can have different incubation needs)

- Age of the breeding stock

- Equipment parameters

For this reason, it is important to consult the incubator manufacturer, as well as a hatchery expert before setting your formats.

Temperature

Temperature profiles are determined by the type of hatchery and incubators. As mentioned above, adjustments may be necessary, depending on the age of the breeding stock, the size of the eggs, and the previous stocking duration. The period of the year, the type of machines and of the loading, the number of eggs, the incubated breed may also impact on the incubation temperature settings

Generally, the optimum incubation temperature, the internal temperature of the egg, is from 37.77°C to 38.33°C (100°F- 101°F). Especially if the hatchery is using a multiple stage incubator, it is important to be cautious that the correct temperature profile is achieved for the embryonic stage. Discrepancies 10% in the eclosion rates can be observed between the coldest and warmest areas of the incubator. Overheating the embryo, over 40˚C (104˚F) can cause multiple malformations.

Ventilation

Though a critical parameter, this factor is often misunderstood. Gas exchanges in the incubator is of crucial importance for the development of the embryo.

Poor exchanges between oxygen and carbon dioxide may be due to:

- A deficient ventilation of the incubator (settings)

- A deficient ventilation of the incubation rooms

- A poor porosity of the shell limiting gas exchanges

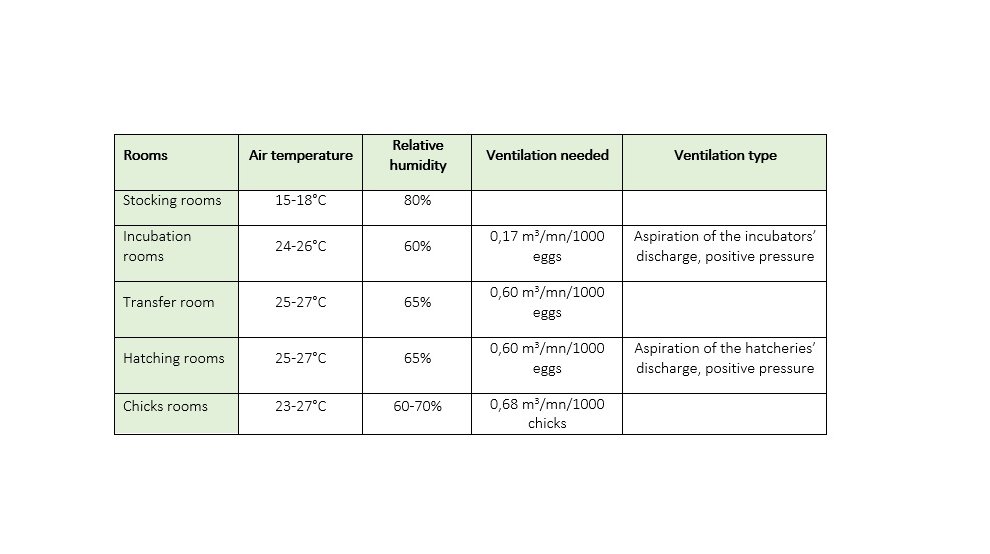

By essence, a ventilation system has to supply the hatchery with fresh and clean air and extract polluted air. Air conditioning and filtration are needed in most of the hatchery’s rooms (warming, cooling, moisturizing or drying). It has to be appropriately modified according to each room’s needs, seasons and climatic conditions. Most incubators run with a 55% relative humidity.

Multi stage machines require a regular flow adjusted according to CO2 concentration. The maximum CO2 concentration equals 0.5%; however, fixed trays machines can sit between 0.2 to 0.3% and trolley machines 0.3 to 0.4%. In single stage incubators, CO2 concentration at the first stage should fall between 0.1 to 0.2%, and 0.4 to 0.5% before transfer.

Humidity

During the incubation, water vapour is eliminated through the shells’ pores. The size and number of these pores determines the elimination of water vapour relative to humidity in the incubator. A weight loss of 11 to 12% is recommended for most chickens breeds.

The most accurate method to measure the loss of water in the incubator is to weigh a sample of eggs before loading (e.g. a full tray) and monitor this sample with regular weighing (every 3 days). If the results are different than expected, humidity and ventilation profiles should be revised.

Factors that can affect the rate of water loss are:

- The control of humidity by the machine

- The parents breed (layer or broiler)

- The age of the parent stock

- The size of the eggs

- The quality and porosity of the shell

Turning

To avoid the embryo sticking to the internal membrane of the egg, and to simulate the hen turning eggs in the nest, it is essential that the egg is turned during the first part of the incubation. This turn should be about 45° vertical with the egg pointing downwards. Turning the eggs during incubation also helps the embryo to absorb and utilize albumen and reduce malpositions. A simple implementation for hatcheries is to turn the eggs once per hour. Turning the eggs every 15 or 30 min can increase eclosability in certain cases, for example with brown eggs.

Following these stages, the eggs are transferred to the hatching room and then servicing room. In order to achieve the best possible start for the chicks, proper incubation allows the embryo to successfully reach all biological targets.