Published on Sept. 20, 2019

New production standards show improvement in egg quality

New production standards announced by Hendrix Genetics Layers show the effect of their intensive breeding program. Besides improvement of egg numbers by 14 eggs per hen housed, also an improvement is visible in the aspect of egg quality. The improvements are the result of their extensive and innovative breeding program for the brands Bovans, Hisex, Dekalb, ISA, Shaver and Babcock.

The impact of testing to 100 weeks

When ISA and Hendrix Poultry Breeders merged in 2005, the respective breeding programs became one large operation, where the best of both worlds, in terms of genetic lines, selection methods, data recording and field evaluation programs were combined.

Crucially, in 2008 the testing duration was extended to 100 weeks of age. At that time, Hendrix Genetics Layers were the first and only breeding company keeping the birds to that age, a forward looking decision which has led directly to the significant improved performance results.

The reason for the move to 100 weeks, was the fact that the variance in production between families was getting less and less with the variation having reduced from 25% to 10%. After moving to 100 weeks, the variation between families increased again, towards the end of the cycle, which provided renewed opportunities for selection and genetic improvement.

The best bird at 100 weeks will also be the best one at 90 or 70 weeks but the opposite is not necessarily always the case. That is why Hendrix Genetics measures all its pure line birds until 100 weeks for all the different traits, including egg quality

Phenotyping is the key

The key to improving both egg production and egg quality is phenotyping and whatever the statistical method used, phenotypes need to be collected in a very accurate way. With the extension of the laying cycle a wealth of additional phenotypes became available to the geneticists. From extra egg weights, bodyweights, egg numbers, feed intakes, shell strength, shell color and Haugh Units.

Field performance data

The environment where data collection is done is also important. Pure line animals are kept under extremely high biosecurity standards and are free from diseases, to meet international veterinary demands. That means that data collection at pure line level is done in ‘artificially’ ideal circumstances, and mainly on females.

For international breeding companies this is not enough. Measurements need to be done in practical circumstances. This is why so called “field tests” are used, where birds perform in real housing systems, under different sanitary pressures, water quality, feed quality, temperature and humidity conditions.

All traits measured on pure line birds, including egg quality, are also measured on field test birds. Test birds are all wing-banded and are linked in the inhouse breeding database through pedigree information. The other advantage of field tests is the opportunity to measure the genetic potential in egg numbers and egg quality of the pure line males by placing (half) sib daughter groups in field evaluation tests. Although males don’t lay, they too have a genetic potential for egg number and quality.

These field tests are crucial to the breeding program and to test the performance of crossbred birds in commercial conditions, under the differing climatic conditions found in many parts of the world. The testing of crossbred daughters of male breeding candidates encompasses daily recording of egg numbers and mortality, monitoring of egg weight development, and of course egg quality related traits such as shell strength integrity, shell color intensity, albumen height and Haugh units.

Each year, nine million measurements are done on the eggs laid in the R&D facilities and more than six million measurements on the eggs produced in commercial circumstances, all on an individual basis.

The data is collected with the use of handheld computers and state-of-the-art measurement devices. Data is sent directly from the farms to the central database where it is collated and analyzed using in-house software. Breeding values are determined by pure line, recurrent test and genomic data assessed against the breeding goals for a line.

With all this data Hendrix Genetics can select with a high accuracy the best birds to produce the next generations and to improve performance and profitability for our commercial stock customers.

Focus on Egg Quality

Over 90 traits are measured in the Hendrix Genetics Laying Hen breeding program, of which more than 50 are linked to the quality of table eggs. Egg shell strength is one of the most important and the new 2017 standards show an improvement of 100 grams Breaking Strength. With better shell quality commercial flocks can be kept longer, which will facilitate producers to reach 500 first quality eggs per hen housed in a single cycle to 100 weeks of age.

Shell strength

Across the supply chain different measures of egg quality are applied. Consumers assess egg quality in terms of egg shell breakage, color (intensity and uniformity) and internal quality. Whilst for producers, packers and farmers of commercial flocks, shell strength is a key measure of egg quality.

Fragile eggs are less likely to withstand the packing process that starts in the nest and ends on the supermarket shelf. In many countries eggs are transported over a long distance, over bumpy roads, so in order to protect the valuable egg content, the shell must be in optimum condition.

Improving breaking strength

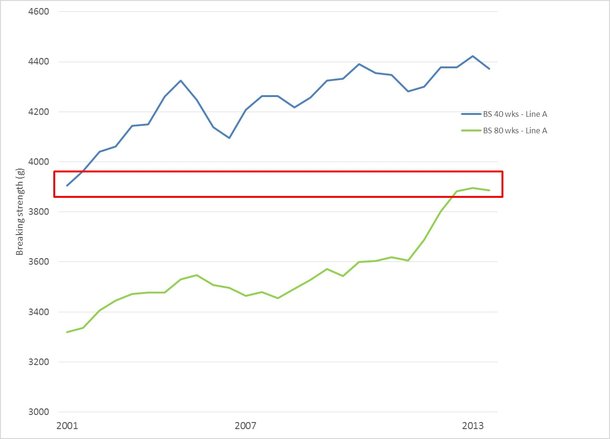

The Hendrix Genetics Layer breeding program is especially focused on improving breaking strength at the end of the cycle, as birds are kept longer. In fact, breaking strength measured at 80 weeks in 2013 was at the same level as it was at 40 weeks in 2001 (around 3950g).

Graph: breaking strength trend over the year measured at 40 weeks (blue) and 80 weeks (green) in grams.

Egg shell color

Shell color is no reflection of internal egg quality or of an egg’s nutritional value. Nevertheless, consumers express clear preferences for shell color, darkness and consistency of shade, although preferences for white or brown eggs differ from country to country and market to market.

Breeding and selection are important for a better egg shell color amongst both white and brown birds. White eggs have to be very white from the beginning. For brown breeds, shell color lightens after 50 weeks making breeding for a darker brown shell color, at the end of lay, a crucial breeding objective. The shell color of the brown breeds is expressed in LAB values, and the new standards show an improvement of 2 units LAB value. This is a significant visible improvement.

Internal egg quality

The most common test for internal egg quality test was invented by Raymond Haugh in 1937. After being weighed, an egg is broken onto a flat surface and a micrometer is used to determine the height of the thick albumen that surrounds the yolk. The height, correlated with the weight, determines the Haugh unit, or HU- rating. The higher the number, the better the internal quality of the egg.

Egg yolk color and composition is predominantly affected by feed composition. However, the albumen ratio, which is important to the food processing industry, which demands good solids (dry matter) in the eggs, is part of the breeding program of Hendrix Genetics.

New standards for Hendrix Genetics layers

The Hendrix Genetics Layers Breeding Program objective of achieving 500 first quality eggs at 100 weeks is on target to replicate the results seen across the testing program, in commercial stocks by 2020. This achievement will be accompanied by concurrent improvements in key parameters of egg quality. In particular, the new standards show an increase in shell strength for both white and brown breeds and shell color improvements in brown breeds.