Published on April 28, 2025

Preventing salmonella contamination via feed

Salmonella remains a significant public health concern, particularly in egg production, as contaminated eggs can be a risky source of human infections. For laying hen breeders, ensuring the safety of feed is crucial in mitigating the risks associated with Salmonella transfer.

Feed mills play a vital role in this process by applying different techniques and steps to prevent contamination at every stage of feed production and storage. Feed contamination accounts for a relatively small but critical percentage of Salmonella sources in poultry (Schothorst Feed Research B.V. 2024). Feed mills play a key role in reducing this risk by implementing preventive measures at various stages.

- Contaminated raw ingredients: Animal by-products, such as meat meal, and oilseed ingredients, such as soybean meal, are common sources of contamination. Animal by-products, in particular, provide an ideal environment for Salmonella to grow and multiply.

- Dust accumulation and inadequate sanitation: Dust in feed mills poses not only an explosion risk but also serves as a significant reservoir of Salmonella, particularly in high-risk areas such as grinding and mixing equipment. Contamination can persist in feed mill environments due to biofilm formation, low moisture conditions, and inadequate cleaning. Identifying, reducing, and monitoring dust accumulation points is essential for effective prevention.

Strategies for preventing Salmonella entry and multiplication

Preventing Salmonella contamination in feed mills starts with controlling raw materials and maintaining rigorous hygiene standards:

- Raw ingredient management: It is generally safer to source ingredients from certified suppliers with strict monitoring programs. Additionally, every batch can be tested and rejected based on quality checks (quality analysis of the material and visual inspection). Cross-contamination can also occur during transport and handling, making it essential to enforce strict hygiene protocols.

- Zoning: Establishing clear distinctions between “dirty” (raw) and “clean” (processed) areas within the mill prevents cross-contamination. Measures, such as colour-coded equipment, foot baths, personal protective equipment, and minimising manual handling, can reduce the risk of Salmonella spread. A one-directional process flow should be maintained to ensure raw and processed feed do not share specific sections of the feed production line.

- Dust control: Regular dust removal, particularly around critical machinery, and maintaining effective dust-handling systems are vital. Sealing seams in key areas can further reduce contamination risks.

- Pest management: Implementing and maintaining pest control measures helps reduce Salmonella transmission via rodents, insects, and wild birds.

- Moisture control: Preventing water accumulation from leaks, condensation, or cleaning processes is crucial to inhibiting microbial growth. Proper storage conditions, including dry environments, adequate ventilation, and temperature control, help minimise Salmonella survival and proliferation. This is valid for all materials and all storage types: feed silos, bags or open storage.

Thermal processing for Salmonella reduction

Thermal processing, such as sanitising, pelleting or expanding, is an essential step in reducing the microbial load of Salmonella in feed:

- Pelleting or expanding: These processes apply high temperatures for short durations. However, there is a risk that the outer layer of pellets is more effectively treated than the inner portion. Therefore, sanitising is recommended over pelleting or expanding when possible.

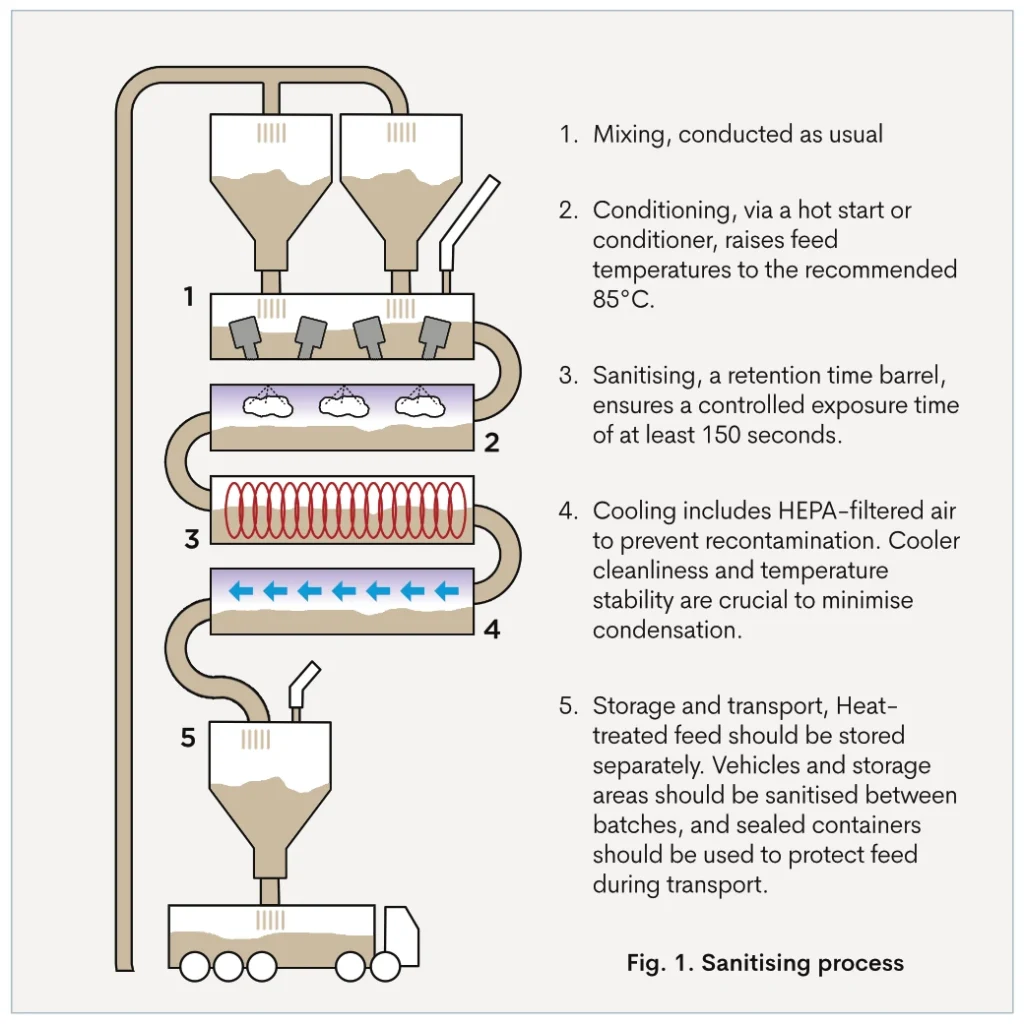

- Sanitising: Heat treatment at approximately 80°C for at least 60 seconds is effective for pathogen reduction. However, increasing the temperature to 85°C for at least 150 seconds provides better control. The process must be carefully managed to balance microbial elimination with nutrient preservation. The advantage of sanitising is the possibility to heat treat mash diets. A sanitising process, such as the one used by feed mill De Hoop see Fig 1.

Preventing recontamination in finished feed

Once feed is processed, preventing recontamination is critical. In addition to the measures above, sanitising additives, such as organic acids, can be used to inhibit Salmonella growth and prevent post-processing contamination. However, regulatory restrictions may limit the use of certain additives, such as formaldehyde, in certain countries. While these strategies are effective, several challenges and increased costs persist. Detection difficulties may persist, as Salmonella is often unevenly distributed in feed, making representative sampling important but difficult. Salmonella can form biofilms and can survive in dry conditions, complicating eradication efforts. Besides, certain legal constraints limit the use of effective pathogen control additives, while others mandate heat treatments. It is also a given fact that not all feed mills are equipped with the necessary sanitising equipment, making it difficult to implement effective treatments without significant investments.

Conclusion

Preventing Salmonella contamination in feed mills requires a multi-faceted approach, combining strict hygiene practices, effective thermal processing, and robust recontamination prevention strategies of finished feed. By addressing contamination risks at the feed mill, egg and poultry producers can significantly reduce the likelihood of Salmonella transmission, an especially critical factor for the players with activities higher along the egg and poultry chain, such as poultry breeders and distributors of day-old chicks.