Published on March 8, 2021

Insects, Feed for the Future?

With the continuously growing world population, the demand for eggs is expected to grow at least as fast. Their high nutritional value, their overall availability and their long-lasting shelf life, combined with affordable prices are the main reasons why the worldwide growth in eggs is so much higher compared to beef or pork.

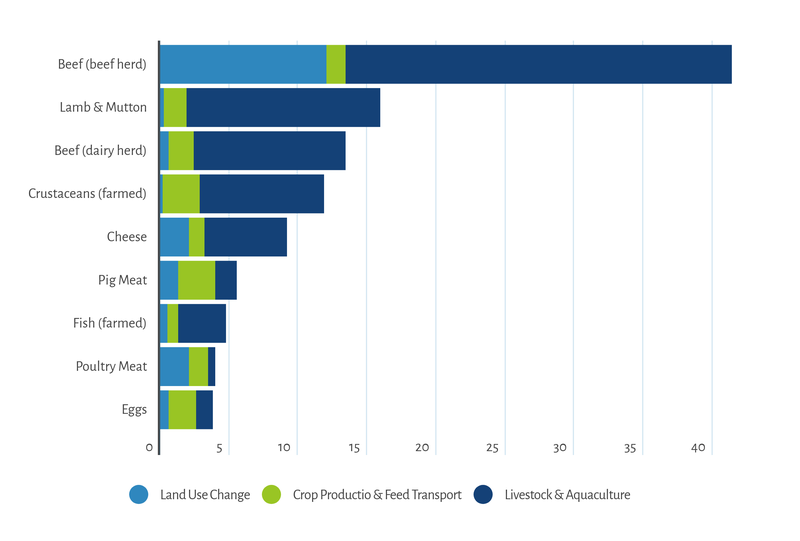

Also, from the environmental perspective, producing one kg of eggs results in the lowest amount of GHG-emissions when compared to Aquaculture and Livestock (Figure 1. Science Magazine). The growth in global egg production requires increasing amounts of protein to cover the amino acid requirements of the birds for their development, their maintenance, their plumage development, and to produce eggs.

Figure 1. Mean GHG emissions of protein-rich products across three major production stages: Land Use Change, Crop Production & Feed Transport, and Livestock and Aquaculture. Derived from Poore & Nemecek (2018).

The Global Challenge

But we know that there is a Global Challenge: with the growing world population, we need to produce more and more food, whilst the surface of arable land is hardly increasing, and we see increasing volumes of bio-waste streams. There is a clear need for innovative solutions to meet this Global Challenge, as it is not likely that we all become vegan in the coming decade.

One of these solutions can be the application of insects, as a sustainable high protein feed ingredient in animal diets (pigs, poultry and aquaculture). Insects can be sustainably reared on bio-waste streams, and as a result of being cold-blooded they have a favorable feed conversion. There is more and more ongoing research on the large-scale utilization of insects as an alternative protein source, e.g. replacing soya in the diets. The use of insects in livestock diets is technically feasible. It is known that insects can be grown on low-grade bio-waste and that they are able to turn this waste into high quality insect protein. Insects can potentially play a big role in the animal feed chain, in order to fulfill the growing global demand for protein. Main bottlenecks at this moment are legislation (in Europe legislation only allows feeding animals with live insects), the achievement of a lower cost price by further automation of the production process, and safety when using bio-waste as a substrate to grow insects on.

The world compound feed production is estimated to be over 1 billion tonnes annually. The FAO1 has estimated that the world must produce 60% more food by 2050 (compared to the production of 2005/07)

Currently, the most important protein sources for animal feed are soybean meal, fish meal and processed animal protein (like blood and bone meal). But they all have their limitations: in the EU, the use of processed animal protein is forbidden; the global land availability to expand soya production in a sustainable way is limited; and overfishing has reduced the availability of forage fish from which fish meal and fish oil is derived. The growing scarcity of resources has led to a significant increase in prices, with prices being more than doubled during the last decade. Alternative sources for (animal) protein, like insects, are therefore urgently needed.

Rich source of protein

Insects are a rich source of protein, essential amino acids and fat. The protein content of insect meals varies considerably from 30 to 70% on a dry matter basis. The same holds true for the fat content. Table 1. shows the protein composition of Black soldier fly larvae and mealworms compared to common feed ingredients (Soybean, Sunflower, Meat and Bone meal, and Fish meal). The protein content of insect species is within the range of soybean and fishmeal, it can be clearly seen that insect meal compared to fishmeal contain lower concentration of methionine (Table 1). Further, the calcium concentration is usually lower than that of fish meal. Larvae of the Black soldier fly do however provide substantially more calcium than mealworms. It is known that the nutrient concentration of insects does not only depend on the life stage of the insect, but also on the growing conditions (e.g. the composition of the growth media used for producing insects).

Growing insects

The robustness of insects is of special interest to grow them, many insects can grow under extreme conditions: low oxygen levels, no lighting and high stocking densities. Currently more research is being done after the nutritional recommendations and optimal housing conditions to optimize the growth of the different insect species. From several species it is known that they can grow on poultry manure. A study from Newton et al (2005) showed that black soldier fly larvae can reduce the accumulation of poultry manure by 50%. Another great advantage of growing insects is that hardly any additional drinking water must be applied: insects are able to utilize water very effectively, with in most cases their feed being the main source of water. Insects are very well capable to utilize some poor-quality raw materials as by-products from food industry, like apple or potato pulps.

Insects can be produced in 3D dimension systems, which allows a very effective usage of the space and buildings to grow them. Their short lifecycles and incredible growth potential can result in the case of black soldier fly larvae in 180 kg of live weight in 42 days, from just 1 m² (Józefiak and Engberg, 2015). The growth rate, as well as the feed utilization is highly dependent on the environmental temperature, for most insects this is optimal at 27-30°C.

Of very high importance to safeguard the safe production of insects is biosecurity. Insects should not be able to escape from their captive environment. Most of them needs to be regarded as invasive species and you do not want them to interfere with the natural environment. Like with poultry, it is advised to apply the “all in all out” system per growing unit. It is important that the insects do not get contaminated when feeding on contaminated by-products. When feeding the insects with by-products, it is of high importance to safeguard the quality of the by-products.

Inclusion in poultry diets

Many trials have been performed that involve diets containing different insect meals or feeding live larvae to the birds. Inclusion of insects or insect meals to the diet could potentially replace the usage of soy and could also improve the welfare of the birds, e.g. reducing feather pecking. Results from Schothorst Feed Research (2020) indicated that replacing soy with live black soldier fly larvae and other local protein sources had no adverse effect on production performance and egg quality. Additionally, random and steady provision of larvae to older laying hens with intact beaks had also a positive effect on feather condition. A meta Analyses performed by Moula et al (2019) showed that insects should substitute only partially conventional protein sources to guarantee the appropriate growth of birds. In these cases, the inclusion of insects (mostly black soldier fly larvae, mealworms and maggots) had no overall adverse effect on the average daily gain, feed intake and Feed Conversion Ratio in broilers.

Table 1 Values as DM (per kg DM)

| Nutrient | Unit | Soybean meal CP 46.4 | Soybean meal CP 42,6 | Rapeseed meal | Sunflowerseed meal | Meat and Bone meal | Meat Meal | Fish Meal |

Black soldier fly larvae (dehydrated) |

Mealworm |

|---|---|---|---|---|---|---|---|---|---|---|

| Ash | g | 70 | 70 | 75 | 75 | 378 | 230 | 184 | 206 | 31 |

| CP | g | 529 | 486 | 387 | 395 | 480 | 594 | 689 | 421 | 528 |

| Acid Ether Extract | g | 27 | 36 | 47 | 29 | 143 | 144 | 107 | 260 | 361 |

| LYS | g | 32,8 | 30,1 | 21,3 | 13,8 | 23,0 | 30,3 | 52,4 | 27,8 | 28,5 |

| MET | g | 7,4 | 6,8 | 7,8 | 8,7 | 6,2 | 7,7 | 19,3 | 8,8 | 7,9 |

| CYS | g | 7,9 | 7,3 | 9,7 | 6,7 | 3,8 | 5,9 | 6,2 | 0,4 | 4,2 |

| M+C | g | 15,3 | 14,1 | 17,4 | 15,4 | 10,1 | 13,7 | 25,5 | 9,3 | 12,1 |

| THR | g | 20,6 | 18,9 | 17,0 | 14,6 | 14,4 | 19,6 | 28,9 | 15,6 | 21,1 |

| TRP | g | 6,9 | 6,3 | 5,1 | 4,7 | 2,4 | 4,2 | 7,6 | 2,1 | 3,2 |

| ILE | g | 24,3 | 22,3 | 15,1 | 16,2 | 12,5 | 16,6 | 28,9 | 21,5 | 24,3 |

| ARG | g | 39,7 | 36,4 | 23,6 | 32,0 | 36,0 | 41,0 | 40,6 | 23,6 | 25,3 |

| PHE | g | 27,5 | 25,3 | 15,9 | 18,2 | 15,4 | 20,8 | 26,9 | 21,9 | 21,1 |

| HIS | g | 14,3 | 13,1 | 10,8 | 9,9 | 8,6 | 11,3 | 17,9 | 12,6 | 18,0 |

| LEU | g | 40,7 | 37,4 | 27,1 | 24,9 | 26,4 | 36,8 | 50,3 | 33,3 | 45,4 |

| TYR | g | 19,6 | 18,0 | 12,0 | 9,9 | 9,6 | 13,7 | 21,4 | 29,0 | 39,1 |

| VAL | g | 25,4 | 23,3 | 19,8 | 19,3 | 19,2 | 26,7 | 33,8 | 34,5 | 31,7 |

| ALA | g | 23,3 | 21,4 | 17,4 | 17,0 | 38,9 | 45,8 | 43,4 | 32,4 | 38,5 |

| ASP | g | 61,4 | 56,4 | 29,0 | 36,3 | 36,0 | 46,4 | 64,1 | 46,3 | 39,6 |

| GLU | g | 94,2 | 86,5 | 65,5 | 76,2 | 57,6 | 73,1 | 89,6 | 45,9 | 59,7 |

| GLY | g | 22,7 | 20,9 | 20,1 | 22,5 | 75,3 | 76,7 | 44,8 | 24,0 | 25,9 |

| PRO | g | 27,0 | 24,8 | 23,3 | 17,0 | 45,1 | 52,3 | 30,3 | 27,8 | 35,9 |

| SER | g | 27,0 | 24,8 | 17,0 | 17,0 | 18,2 | 24,4 | 27,6 | 13,1 | 37,0 |

| Sum_AA | g | 522,7 | 479,9 | 347,8 | 364,6 | 448,6 | 553,3 | 633,8 | 414,3 | 497,4 |

| Ca | g | 3,5 | 3,5 | 8,8 | 3,9 | 137,8 | 60,8 | 44,0 | 75,6 | 27,0 |

| P-total | g | 7,3 | 7,5 | 11,8 | 11,5 | 66,3 | 33,7 | 28,7 | 9,0 | 7,8 |

| Phytate P | g | 5,1 | 5,2 | 8,9 | 9,2 | |||||

| Mg | g | 3,4 | 3,4 | 4,6 | 6,3 | 2,8 | 2,0 | 2,5 | 3,9 | 2,3 |

| K | g | 25,0 | 25,0 | 14,4 | 16,7 | 3,3 | 5,4 | 9,0 | 6,9 | 8,9 |

| Na | g | 0,2 | 0,2 | 0,4 | 0,2 | 6,7 | 7,4 | 11,5 | 1,3 | 0,9 |

| Cl | g | 0,5 | 0,5 | 0,4 | 1,2 | 4,3 | 7,3 | 16,6 | ||

| Fe | mg | 344 | 344 | 503 | 262 | 1235 | 381 | 57 | ||

| Mn | mg | 42 | 42 | 79 | 49 | 39 | 19 | 246 | 9 | |

| Zn | mg | 55 | 55 | 69 | 101 | 111 | 128 | 90 | 108 | 116 |

| Cu | mg | 17 | 17 | 6 | 37 | 10 | 16 | 8 | 6 | 16 |

Forecast

As mentioned before, there is no doubt that insect meals from a nutritional perspective are suitable for feeding laying hens. However, several barriers still exist to allow insect meals in the diets. One of them is legislation: we take the EU as an example. EU-legislation defines insect meals being processed animal protein (PAP). Insects and other invertebrates are classified as Category 3 material (fit but not intended for human food chains). As such, they are suitable as feed for livestock (poultry, pigs, fish). However, the BSE (mad cow disease) regulation prohibits the feeding of farmed animals with PAPs. But positive developments are on its way: the feeding of insect meals to aquaculture species is going to be allowed and a re-authorization of these PAPs for pig and poultry feed is expected in the year(s) to come. Now, the largest challenges to overcome are the limited quantities produced and the high price. Currently prices for insects and insect meals are very high and cannot compete with other available protein sources. As more and more companies are investing in the production and in the breeding of insects, it is highly likely that the cost of production will go down in the years to come, making insect meal more competitive and available to include in poultry diets.

References

- FAO, World Agriculture Towards 2030/2050: The 2012 revision: http://www.fao.org/fileadmin/user_upload/esag/docs/AT2050_revision_summary.pdf

- Józefiak and Engberg (2015) “Insects as Poultry Feed” Józefiak D. 1, Engberg R.M., 2, 1 Poznan University of Life Science, ul. Wolynska 33, 60637 Poznan, Poland; 2 Aarhus University, Blichers Allé 20, 8830 Tjele, Denmark. Presented during the 20th European Symposium on Poultry Nutrition | 24–27 August 2015 | Prague, Czech Republic

- Moula et al., (2019) “A Meta-Analysis of the Effects of Insects in Feed on Poultry Growth Performances” Moula N., DetilleuxJ., University of Liège, 4000 Liège, Belgium. Published: 28 April 2019

- Poore J., and Nemecek T., (2018) Reducing food’s environmental impacts through producers and consumers. Science 360(6392), 987-992 DOI: 10.1126/science.aaq0216. Published online 31 May, 2018

- Schothorst Feed Research (2020) “Gradual Provision of Live Black Soldier Fly (Hermetia illucens) Larvae to Older Laying Hens: Effect on Production Performance, Egg Quality, Feather Condition and Behavior”. Authors: Star L. 1, Arsiwalla T. 2, Molist F. 1, Leushuis R. 2, Dalim M. 2, Paul A. 2, *1 Schothorst Feed Research B.V., 8218 NA Lelystad, The Netherlands; 2 Protix B.V., 5107 NC Dongen, The Netherlands. Published: 28 January 2020