Published on Dec. 28, 2023

Navigating Nitrogen: Challenges Confronting Dutch Livestock Farmers

In the idyllic landscapes of the Netherlands, where lush fields meet bustling cities, a pressing concern casts its shadow over the livelihoods of livestock farmers. Nitrogen emissions or more specific nitrogen deposition, arising from farming practices and fossil fuel combustion, have emerged as a formidable challenge. These emissions, composed of compounds like ammonia and nitrous oxide, extend beyond the farm gates, affecting both local ecosystems and human health.

As the Netherlands grapples with densely populated regions and a thriving agricultural sector, the delicate balance between nourishing the nation and preserving the environment is strained. Stringent regulations, designed to safeguard air quality and protect sensitive habitats, have prompted farmers to navigate a complex regulatory landscape. The intricate interplay between livestock farming's economic significance, livability in rural areas and environmental impact has led to a pressing need for sustainable solutions. Against this backdrop, Dutch livestock farmers find themselves at the forefront of a multifaceted battle: sustaining their livelihoods while addressing the urgent issue of nitrogen emissions.

Luckily, an increasing number of innovative technologies, insights and best practices are being developed that can be used in modern poultry farming to address emissions, including:

- Biofilters: Biofiltration systems use microorganisms to break down and convert pollutants in the air, such as ammonia and volatile organic compounds (VOCs), into less harmful substances. These systems can help improve air quality and reduce odors around poultry facilities.

- Scrubbers: Air scrubbers or exhaust air cleaning systems are designed to remove particulate matter and gases from the exhaust air of poultry houses. They can help reduce emissions of dust, ammonia, and other pollutants.

- Manure Management: Proper management of poultry manure is crucial to reduce emissions. Technologies such as anaerobic digesters can convert manure into biogas, which can be used as an energy source, thereby reducing greenhouse gas emissions.

- Ventilation Systems: Modern ventilation systems in poultry houses are designed to optimize air exchange, temperature, and humidity. Proper ventilation not only improves the health and productivity of the birds but also helps control emissions.

- Alternative Bedding Materials: Using alternative bedding materials, such as wood shavings or rice hulls, can help reduce ammonia emissions compared to traditional straw bedding.

- Nutrition Management: Adjusting the diet of poultry to reduce excess nitrogen can also help lower ammonia emissions from manure.

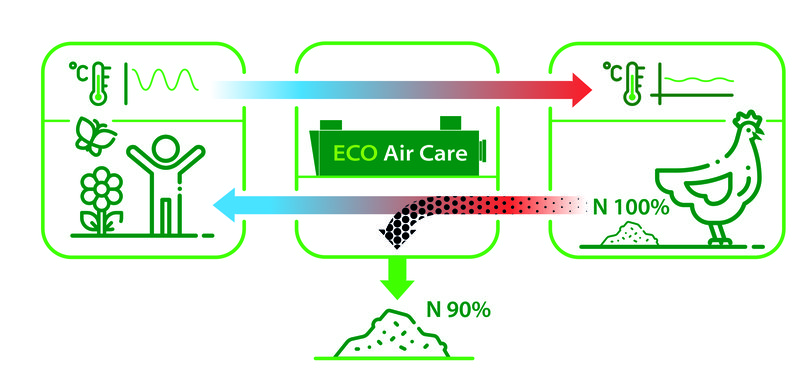

One of the latest innovations involves utilizing air treatment units that combine heat exchange, cooling of the incoming air, and acid air scrubbing of the outgoing air, reducing nitrogen emissions by up to 90%.

So, how does a heat exchanger work? It channels the outside air through plastic fins (air ducts) that are nearly 8 meters long, while exhaust air circulates around these fins in counterflow. The fresh outside air is warmed by the heated, stale air from the poultry house, allowing for efficient heat exchange. The pre-heated air entering the barn helps keep the litter dry. The comprehensive climate control system offers both heating in winter and cooling in summer. To facilitate cooling, the units are equipped with a water tank and spray nozzles that distribute water over the air ducts. To complete the loop, the water is continually recycled using a circulation pump system. In the end, heat exchangers play a vital role in significantly enhancing the indoor climate of the poultry barn, promoting the well-being of the birds and boosting the overall profitability of the farm. Gas is essential as a heating source to maintain optimal conditions for pullets. With an ECO Unit bringing in preheated air, annual gas savings of up to 75% can be achieved. Most egg producers have only ventilation systems and lack heating installations. Consequently, during colder periods, laying hens need to maintain their own body temperature by increasing their feed intake. Hens can use the energy from feed to produce eggs rather than maintain their body temperature. Of course, a heat exchanger does consume electricity, but the overall savings are significant.

The ECO Air Care solution doesn't end here; it has been further developed by the Vencomatic Group and actively removes nitrogen from the stale air. The Eco Air Care units clean the outgoing air by flushing it with process water containing sulfuric acid. The process water captures the emissions of ammonia, particle matter and the odor. This flushing water is collected in a silo and can be used on the farmland as a substitute for fertilizer and thereby contribute to circular farming. Poultry farmers are pleased not only with the demonstrably improved results in their flocks due to better air quality but also because it has been proven that 90% of the nitrogen is removed from the outgoing air.

The ammonia levels (which consists of more than 80% nitrogen) are removed from the air and are measured continuously with ammonia sensors. This means that thousands of kilograms of nitrogen can be captured per barn per year. In the first ECO Air Care barn installation in the Netherlands, we have evidence: 7,000 kg of nitrogen was captured annually, enough to offset the construction of a thousand new homes!

Nitrogen reductions continue to challenge the Dutch farmers, industry, and political environment. Innovations like these will hopefully help to contribute ways towards a sustainable tomorrow. Discover more about the Vencomatic ECO Air Care